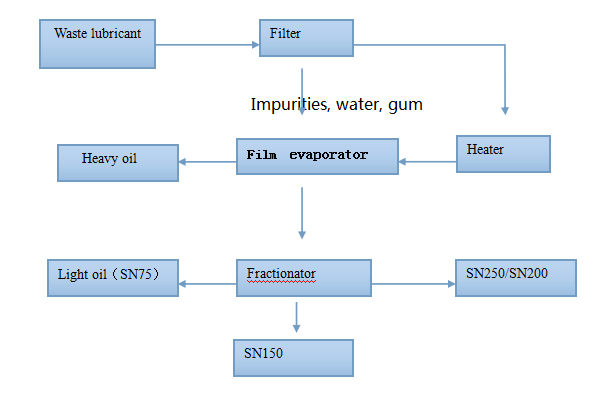

Flow chart

Brief description of the process:

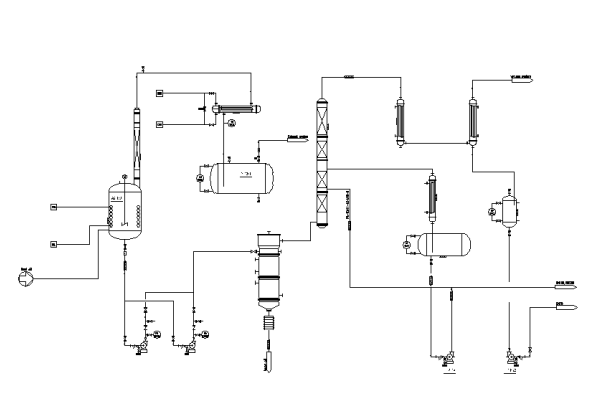

The waste lubricating oil is filtered, precipitated and flocculated to remove some impurities and moisture. Then enter the heat exchange device, heat up to remove impurities,

Then enter the atmospheric tower, by controlling the temperature of the inlet and outlet, in the gasoline and diesel fractionation tower (under vacuum), separate gasoline and diesel components in the waste engine oil. The separated materials are reheated and enter the thin film evaporator (under high vacuum conditions).

The top weather enters the fractionation tower, and the fractionation tower produces light oil, SN150 and SN250.

The heavy components at the bottom of the evaporator are sent to the cooling storage system or to the cracking system for processing of regenerated diesel.

The separated base oil is sent to the refining process to obtain various pure base oils (mainly 150SN, 250SN).

The fractionated base oil is sent to the base oil blending and refining workshop.

Index

No. | Name | Unit | Technology index | Remark | |

Light base oil | Medium base oil | ||||

| 1 | Exterior | Transparent | Transparent | ||

| 2 | Chroma | 1.5-3 | |||

| 3 | Water content | %(W/W) | Trace | Trace | |

| 4 | Flash point(opening) | ℃ | ≥190 | ≥215 | |

| 5 | Ash | %(W/W) | 0.005 | 0.005 | |

| 6 | Residual carbon | %(W/W) | ≤0.13 | ≤0.13 | |

| 7 | Viscosity (40℃) | mm2/s | 16~45 | 45~65 | |

| 8 | Viscosity (100℃) | mm2/s | Report | Report | Determined by raw material |

| 9 | Viscosity index | Report | 》95 | ||

| 10 | Pour point | ℃ | -15 | -15 | |

| 11 | Corrosion (xopper,100℃,3h) | Qualified | Qualified | ||